What’s in the (Bike) Box?

Questions are from Ben tabor at True Quality Engineering, Responses by PEDAL AND PACK STUDIOS, Part 1

How can bike packaging increase bike value and help brands reach sustainability/waste reduction goals?

The top priority for customers and brands is to make sure that bikes arrive to customers damage free. Any damage to a bike automatically is the least sustainable outcome. The highest value that brands can provide to customers is ensuring the bike arrives in pristine condition, reducing customer service inquiries and quality-related issues from the very first ride!.

In the case of direct-to-consumer (D2C) bikes, packaging serves a dual role: informing the customer and guiding them through the assembly process with clear technical instructions and the specific tools needed for assembly. Effective packaging can also communicate the brand's messages and priorities and foster a sense of connection and confidence in the customer's purchase. Poor packaging and inadequate technical and assembly information can hurt the customer experience from day one.

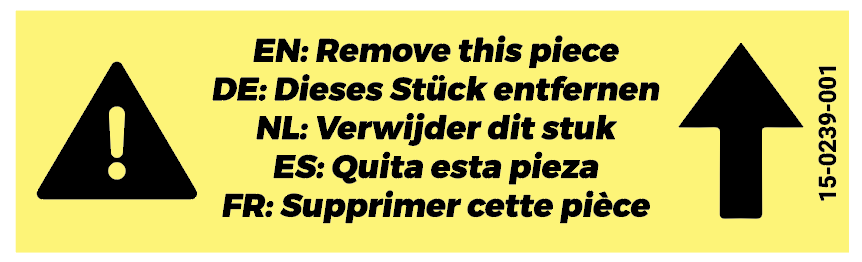

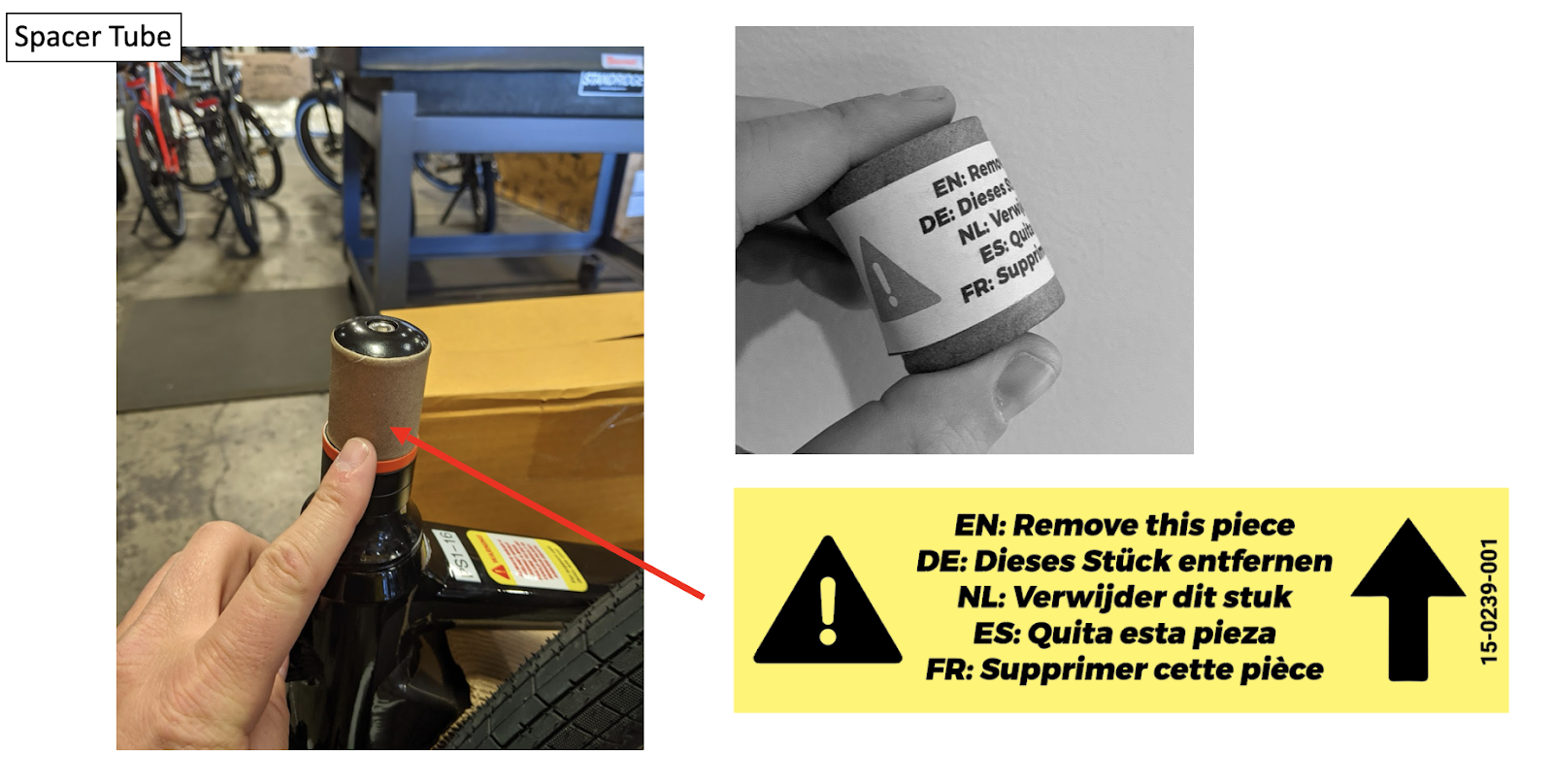

You have one shot to make a good first impression with customers, whether they are buying directly or through bike shops. Prevent situations that may confuse the customer or assembly mechanic. Haphazard packaging or unlabeled parts in the box impact the brand's reputation and lead to doubts about the bike's quality. I've witnessed instances where assembly mechanics attempted to fabricate solutions to non-existent problems due to poor communication or missing or improperly labeled parts.

Good packaging ensures everyone is excited and onboard for the new ride!

Challenges in Bike Shipment Packaging: D2C vs. Brick and Mortar Retail

Direct-to-consumer packaging has a different job compared to traditional retail packaging. D2C packaging requires the bike to be more assembled and ready to ride out of the box. While an assembly mechanic can add a missing part for a traditional retail bike, the same situation creates costly service calls and communications for direct-to-consumer brands. Therefore, packaging should closely align with the bike's development and factory assembly and adjustment, ensuring a smooth customer journey and minimizing frustrations.

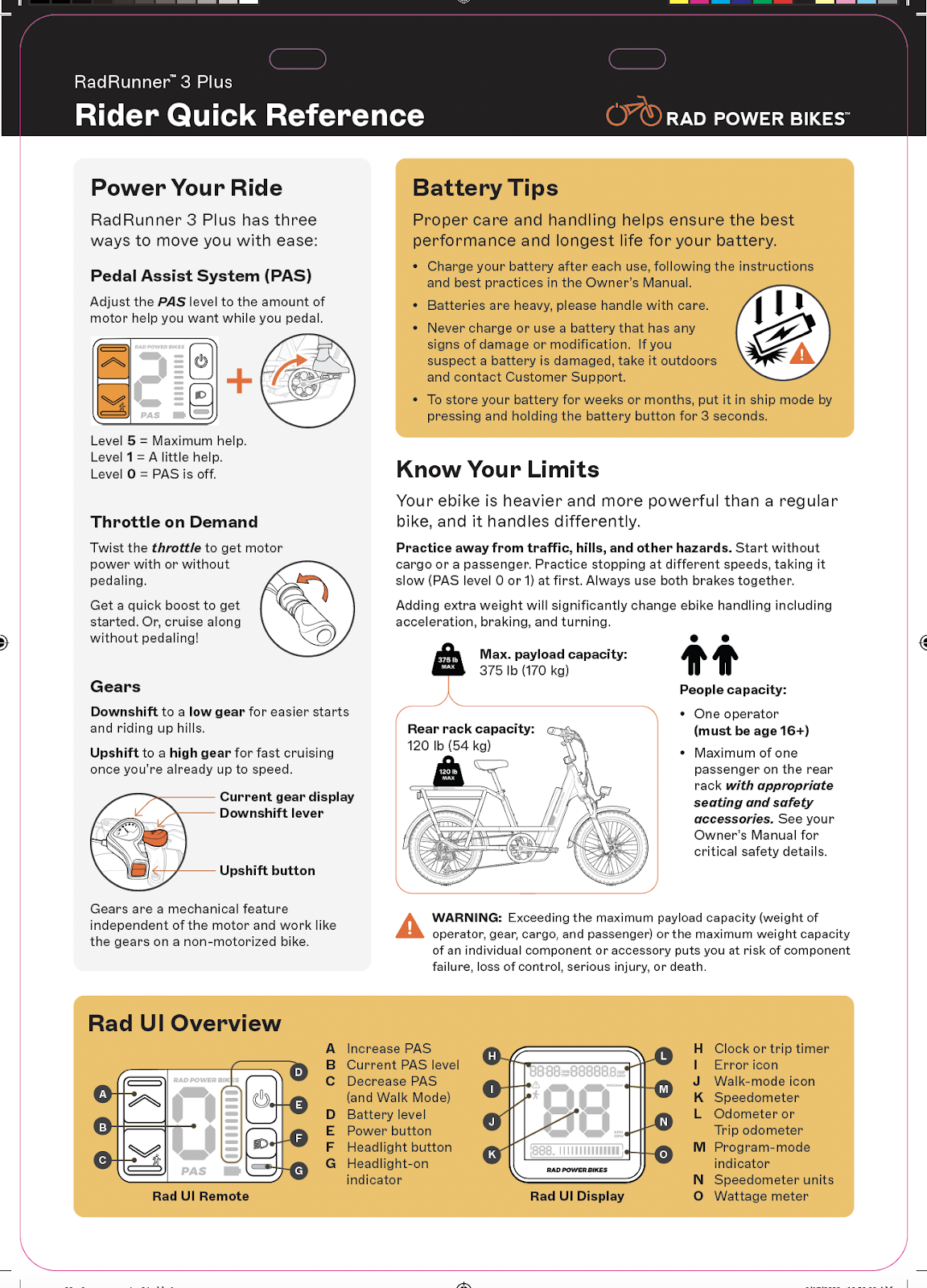

Use QR codes and provide comprehensive starter kits with the necessary tools to assist customers. For example, direct-to-consumer technical instructions emphasize using the correct torque specs for components like a stem faceplate. Different types of bikes may have distinct hardware requirements, and clear guidance is essential to prevent issues, such as stripped bolts. To avoid such problems, some direct-to-consumer brands like Canyon include easy-to-read flex gauges and torque tools in their kits.

Another common challenge is ensuring delicate wiring harnesses and cable routing are protected. Poor handling of these parts can become a massive headache for customers and brands. Packaging should guide customers step-by-step through wheel installation and cable routing, using video content and well-written manuals. A well-crafted “Quick start guide” can simplify user experiences and prevent frustrated calls and emails to customer service.

An example of a well crafted quick start guide from Rad Power Bikes :

Quality customer service is closely linked to packaging, as engineers and quality control teams should collaborate with customer service to address packaging-related quality and damage issues. For instance, if a bike factory's assembly process doesn’t follow your exact documentation and customer instructions, complaints will follow. . Get support from your vendors and QC staff to make sure all packaging follows your requirements 100%.

Example of a good assembly video: https://www.youtube.com/watch?v=weyOy1lPBVs&list=WL&index=72 (From Specialized University)

Stay Tuned for more articles from Pedal and Pack on Bike Industry packaging.